13+ Delayed coking process animation information

Home » Background » 13+ Delayed coking process animation informationYour Delayed coking process animation images are ready in this website. Delayed coking process animation are a topic that is being searched for and liked by netizens now. You can Find and Download the Delayed coking process animation files here. Download all royalty-free photos and vectors.

If you’re searching for delayed coking process animation images information linked to the delayed coking process animation keyword, you have pay a visit to the ideal site. Our site frequently gives you hints for seeing the maximum quality video and picture content, please kindly hunt and locate more enlightening video content and images that fit your interests.

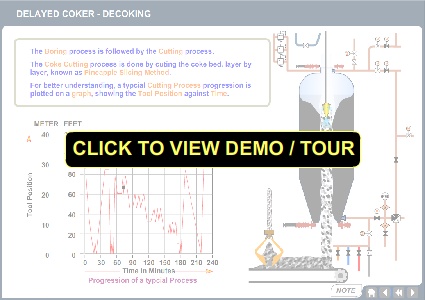

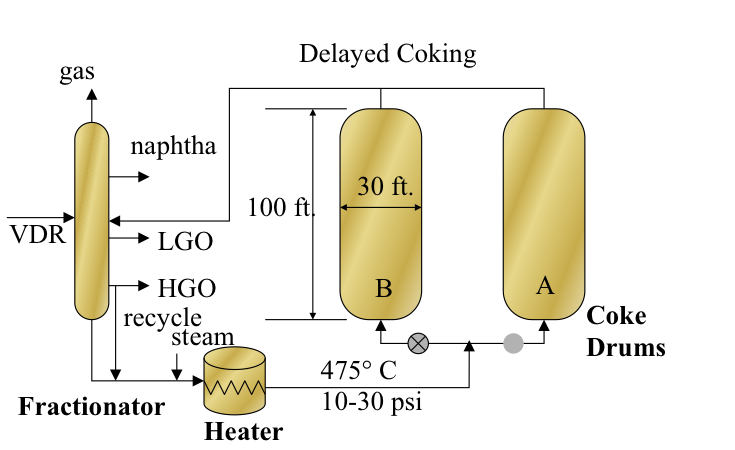

Delayed Coking Process Animation. It is based upon a rigorous and High-Fidelity mathematical process model to provide a realistic dynamic response of a process unit. A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. Heavy streams such as cat cracker slurry oil Slop oils through the closed blowdown system Refinery wastes and sludges in the coke drum quenching step Delayed Coking and the Environment. In a Refinery the Delayed Coker Unit Process is a type of Coking Process where residual oil from vacuum distillation column is converted to low molecular weight hydrocarbon gases naphtha etc.

Plane Delay Motion Design Motion Delayed From pinterest.com

Plane Delay Motion Design Motion Delayed From pinterest.com

The Simulator allows a. Delayed coking is a thermal cracking process to upgrade and convert petroleum residuum into liquid and gas product streams leaving behind a solid concentrated carbon material petroleum coke. The feed to coker is usually vacuum residue which is high on asphaltenes resins aromatics. MODERN DELAYED COKING PROCESS The delayed coker is the only main process in a modern petroleum refinery that is a batch-continuous process. The feed stream is switched between two drums. The dried coal or coke is a solid fuel and is used for many industrial fueling purposes.

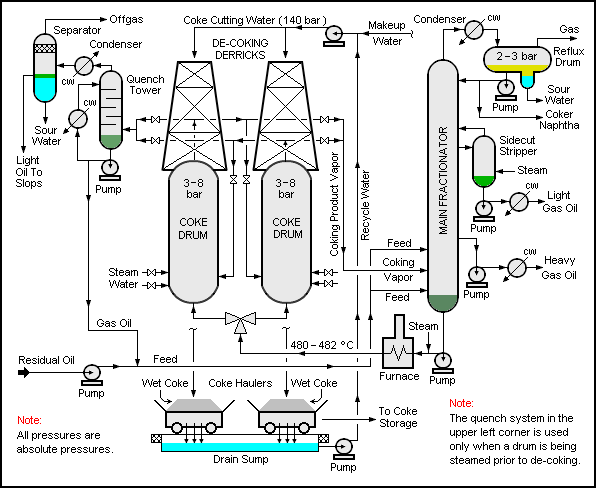

Two diagrams are essential in this effort Figure 1 the process flow diagram PFD and Figure 2 coke drum schematic.

The delayed coking process allows manufacturers to develop two separate fuel sources. Delayed coker unit animation Title. A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. The delayed coking process allows manufacturers to develop two separate fuel sources. The flow through the tube furnace is continuous. The process involves adding small amounts of cracking catalyst and hydrogen to the hydrocarbon feedstock before it is charged to the coking drum.

Source: hive.blog

Source: hive.blog

Vacuum residue enters the bottom of the flash zone in the distillation column or just below the gas oil tray. The process includes a furnace two coke drums fractionator and stripping section. The process involves adding small amounts of cracking catalyst and hydrogen to the hydrocarbon feedstock before it is charged to the coking drum. The feed stream is switched between two drums. Delayed Coking Delayed coking is a type of thermal cracking in which the heat required to complete the coking reactions is supplied by a furnace while coking itself takes place in drums operating continuously on a 24 h filling and 24 h emptying cycles.

Source: yesyen.com

Source: yesyen.com

The process involves adding small amounts of cracking catalyst and hydrogen to the hydrocarbon feedstock before it is charged to the coking drum. High Sulfur coke 4 priced for its heating value in. Process Description A schematic flow diagram of the delayed coking is shown in Figure below. Maximum yield of clean liquid products. Two diagrams are essential in this effort Figure 1 the process flow diagram PFD and Figure 2 coke drum schematic.

Source: yesyen.com

Source: yesyen.com

The feed stream is switched between two drums. In this section the delayed coking process will be described by walking through the individual pieces of equipment with a brief description of the various process steps within the equipment. Process Description A schematic flow diagram of the delayed coking is shown in Figure below. Delayed Coker Units Hot residual oil is fed to the bottom of a fractionator. The feed to coker is usually vacuum residue which is high on asphaltenes resins aromatics.

Source: free3d.com

Source: free3d.com

Delayed Coker Unit Process Animation. Delayed Coker Unit Process Animation. The dried coal or coke is a solid fuel and is used for many industrial fueling purposes. In a Refinery the Delayed Coker Unit Process is a type of Coking Process where residual oil from vacuum distillation column is converted to low molecular weight hydrocarbon gases naphtha etc. The flow through the tube furnace is continuous.

Source: yesyen.com

Source: yesyen.com

This cracks the heavy long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke. A fired heater with horizontal tubes is used in the process to reach thermal cracking temperatures of 485 to 505oC. In the Delayed Coking Process the residual oil is heated to its cracking temperature in a. Delayed coker unit animation Title. In its simplest terms delayed coking is a semi-batch thermal cracking process using alternating drums that are switched offline after filling.

Source: jonellsystems.com

Source: jonellsystems.com

The adjacent photograph depicts a delayed coking unit with 4. One drum is on-line filling with coke while the other drum is being steam-stripped cooled decoked pressure. Heavy streams such as cat cracker slurry oil Slop oils through the closed blowdown system Refinery wastes and sludges in the coke drum quenching step Delayed Coking and the Environment. Radiometric Level And Density Measurement Gammapilot Fmg50 Endress Hauser Source. Advantages and Benefits of Delayed Coking.

Source: pinterest.com

Source: pinterest.com

Radiometric Level And Density Measurement Gammapilot Fmg50 Endress Hauser Source. A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. The Simulator allows a. All of the heat necessary for coking is provided in the heater whereas coking takes place in the coke drum. Hence the process is called delayed coking The hot product vapors and steam from the top of the drum are quenched by the incoming feed in the fractionator to prevent coking in the fractionator and to strip the lighter components of the vacuum residue feed.

Source:

Full range of lighter products Complete decarbonization of residue feed and metals removal. Shot coke is the most common and consist of balls of. In a Refinery the Delayed Coker Unit Process is a type of Coking Process where residual oil from vacuum distillation column is converted to low molecular weight hydrocarbon gases naphtha etc. It is based upon a rigorous and High-Fidelity mathematical process model to provide a realistic dynamic response of a process unit. The dried coal or coke is a solid fuel and is used for many industrial fueling purposes.

Source: en.wikipedia.org

Source: en.wikipedia.org

Low pressure coking ultra-low recycle coking. The Coker unit is very useful for reprocessing or disposing of all kinds of refinery streams. In its simplest terms delayed coking is a semi-batch thermal cracking process using alternating drums that are switched offline after filling. The feed stream is switched between two drums. Delayed Coker Simulation and Tutorial Simulation GSEs EnVision simulation is a real-time dynamic process simulation program used for Operator Training.

Source: gifer.com

Source: gifer.com

Delayed coking is one of the unit processes used in many oil refineries. It is based upon a rigorous and High-Fidelity mathematical process model to provide a realistic dynamic response of a process unit. A fired heater with horizontal tubes is used in the process to reach thermal cracking temperatures of 485 to 505oC. Hence the process is called delayed coking The hot product vapors and steam from the top of the drum are quenched by the incoming feed in the fractionator to prevent coking in the fractionator and to strip the lighter components of the vacuum residue feed. The catalyst settles out in.

Source: jonellsystems.com

Source: jonellsystems.com

In its simplest terms delayed coking is a semi-batch thermal cracking process using alternating drums that are switched offline after filling. It may take one of three different forms depending on the temperatures and pressure applied during delayed coking. Delayed coker unit animation Title. Heavy streams such as cat cracker slurry oil Slop oils through the closed blowdown system Refinery wastes and sludges in the coke drum quenching step Delayed Coking and the Environment. The feed to coker is usually vacuum residue which is high on asphaltenes resins aromatics.

Source: jonellsystems.com

Source: jonellsystems.com

A catalytic delayed coking process is disclosed that gives increased distillate yield and reduced coke make. Heavy streams such as cat cracker slurry oil Slop oils through the closed blowdown system Refinery wastes and sludges in the coke drum quenching step Delayed Coking and the Environment. All of the heat necessary for coking is provided in the heater whereas coking takes place in the coke drum. The dried coal or coke is a solid fuel and is used for many industrial fueling purposes. Vacuum residue enters the bottom of the flash zone in the distillation column or just below the gas oil tray.

Radiometric Level And Density Measurement Gammapilot Fmg50 Endress Hauser Source. Two diagrams are essential in this effort Figure 1 the process flow diagram PFD and Figure 2 coke drum schematic. In a Refinery the Delayed Coker Unit Process is a type of Coking Process where residual oil from vacuum distillation column is converted to low molecular weight hydrocarbon gases naphtha etc. The delayed coking process allows manufacturers to develop two separate fuel sources. Hence the process is called delayed coking The hot product vapors and steam from the top of the drum are quenched by the incoming feed in the fractionator to prevent coking in the fractionator and to strip the lighter components of the vacuum residue feed.

Source: youtube.com

Source: youtube.com

In this section the delayed coking process will be described by walking through the individual pieces of equipment with a brief description of the various process steps within the equipment. All of the heat necessary for coking is provided in the heater whereas coking takes place in the coke drum. Shot coke is the most common and consist of balls of. Delayed Coking Delayed coking is a type of thermal cracking in which the heat required to complete the coking reactions is supplied by a furnace while coking itself takes place in drums operating continuously on a 24 h filling and 24 h emptying cycles. Two diagrams are essential in this effort Figure 1 the process flow diagram PFD and Figure 2 coke drum schematic.

Source: pinterest.com

Source: pinterest.com

Delayed Coker Unit Process Animation. High Sulfur coke 4 priced for its heating value in. The feed to coker is usually vacuum residue which is high on asphaltenes resins aromatics. In the Delayed Coking Process the residual oil is heated to its cracking temperature in a. A fired heater with horizontal tubes is used in the process to reach thermal cracking temperatures of 485 to 505oC.

Source: e-education.psu.edu

Source: e-education.psu.edu

Process Description A schematic flow diagram of the delayed coking is shown in Figure below. Hence the process is called delayed coking The hot product vapors and steam from the top of the drum are quenched by the incoming feed in the fractionator to prevent coking in the fractionator and to strip the lighter components of the vacuum residue feed. The flow through the tube furnace is continuous. The delayed coking process allows manufacturers to develop two separate fuel sources. MODERN DELAYED COKING PROCESS The delayed coker is the only main process in a modern petroleum refinery that is a batch-continuous process.

Source: jonellsystems.com

Source: jonellsystems.com

High Sulfur coke 4 priced for its heating value in. In its simplest terms delayed coking is a semi-batch thermal cracking process using alternating drums that are switched offline after filling. Low pressure coking ultra-low recycle coking. Delayed coking is a thermal cracking process to upgrade and convert petroleum residuum into liquid and gas product streams leaving behind a solid concentrated carbon material petroleum coke. Two diagrams are essential in this effort Figure 1 the process flow diagram PFD and Figure 2 coke drum schematic.

Source: yesyen.com

Source: yesyen.com

Delayed Coking Delayed coking is a type of thermal cracking in which the heat required to complete the coking reactions is supplied by a furnace while coking itself takes place in drums operating continuously on a 24 h filling and 24 h emptying cycles. Low pressure coking ultra-low recycle coking. The adjacent photograph depicts a delayed coking unit with 4. Delayed Coker Simulation and Tutorial Simulation GSEs EnVision simulation is a real-time dynamic process simulation program used for Operator Training. Full range of lighter products Complete decarbonization of residue feed and metals removal.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title delayed coking process animation by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.

Category

Related By Category

- 49+ Corn husk animals information

- 29++ Chinese year 1968 animal info

- 32++ Do animated gifs work in outlook info

- 22++ Animals in space nasa ideas

- 30+ Dragon nest animation information

- 20++ How to animate over live action ideas

- 20++ Chanel logo animation ideas

- 44++ Animals that went extinct in 2013 ideas

- 37++ Disney pixar animals information

- 31+ Bodyweight animal exercises info