29++ Blanking operation animation ideas in 2021

Home » Background » 29++ Blanking operation animation ideas in 2021Your Blanking operation animation images are available. Blanking operation animation are a topic that is being searched for and liked by netizens now. You can Download the Blanking operation animation files here. Find and Download all free photos.

If you’re looking for blanking operation animation pictures information linked to the blanking operation animation interest, you have visit the right blog. Our site always gives you hints for refferencing the maximum quality video and picture content, please kindly surf and locate more informative video articles and graphics that fit your interests.

Blanking Operation Animation. In this video blanking and punching operation is explained with the help of animation. Link motion is a general category that includes a variety of modified slide motions. The web is created after multiple components have been produced and is considered scrap material. I started designing from th.

Blanking Piercing And Punching Process Animation Lagu Mp3 Mp3 Dragon From m.dragonrest.net

Blanking Piercing And Punching Process Animation Lagu Mp3 Mp3 Dragon From m.dragonrest.net

There is an innovative shifter integrated in its black-panel surface that offers the. Link motion is a general category that includes a variety of modified slide motions. Im Zillu a Motion Graphics Visual Effects Video editor Living in a world where design is not an option I just have to do it. Subject - Manufacturing Processes MetallurgyChapter - Difference between Blanking Piercing Punching Lancing Notching Process Sheet metal WorkingIn toda. Modifying slide motion for specific applications. Full Tutorial of How to Create a Sheet Metal Blanking Process Animation in SolidworksNote.

Modifying slide motion for specific applications.

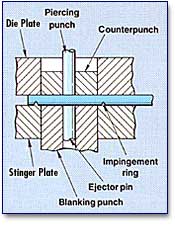

Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable. The process requires a triple-action fine-blanking press. Link motion is a general category that includes a variety of modified slide motions. Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. There is an innovative shifter integrated in its black-panel surface that offers the. Modifying slide motion for specific applications.

Source: pinterest.com

Source: pinterest.com

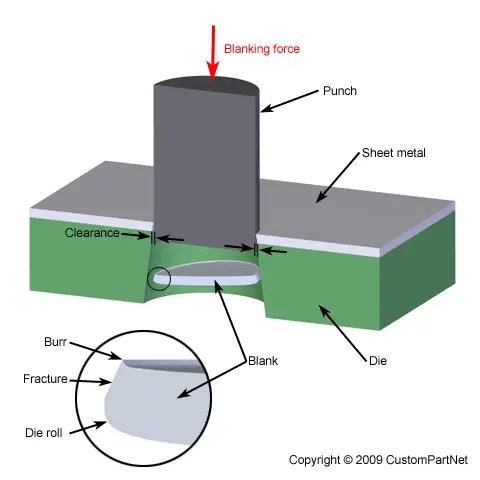

Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations. The design of the center tunnel console is also particularly ergonomic. Full Tutorial of How to Create a Sheet Metal Blanking Process Animation in SolidworksNote. Blanking produces the outside features of the component while piercing produces internal holes or shapes. Operations such as deep drawing forming coining embossing flow control forming cold forging blanking and conventional progressive or transfer die operations.

Source: youtube.com

Source: youtube.com

Press working operations are also known as Sheet Metal OperationsThe operations performed on the sheets to get the required shape is called Sheet metal operations. A typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. Punching or blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable. Modifying slide motion for specific applications.

Source: fineblanking.org

Source: fineblanking.org

This is a Basic Model Animation of Blanking. Modifying slide motion for specific applications. This is a Basic Model Animation of Blanking. In the last article we had discussed Types of dies and Types of fits which are performed on Sheet metal to get the required shape. Punching or blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal.

Source: youtube.com

Source: youtube.com

Link motion is a general category that includes a variety of modified slide motions. The only addition operation needed is the removal of a slight burr. Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. There is an innovative shifter integrated in its black-panel surface that offers the. Subject - Manufacturing Processes MetallurgyChapter - Difference between Blanking Piercing Punching Lancing Notching Process Sheet metal WorkingIn toda.

Source: youtube.com

Source: youtube.com

If the small removed piece is the useful part and the rest is scrap the operation is called blanking. I started designing from th. Im Zillu a Motion Graphics Visual Effects Video editor Living in a world where design is not an option I just have to do it. Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations Ifinfotech posted a video to playlist Manufacturing Processes. The web is created after multiple components have been produced and is considered scrap material.

Source: youtube.com

Source: youtube.com

Punching or blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. Blanking produces the outside features of the component while piercing produces internal holes or shapes. Press working operations are also known as Sheet Metal OperationsThe operations performed on the sheets to get the required shape is called Sheet metal operations. The design of the center tunnel console is also particularly ergonomic. In this video blanking and punching operation is explained with the help of animation.

Source: in.pinterest.com

Source: in.pinterest.com

Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations Ifinfotech posted a video to playlist Manufacturing Processes. I started designing from th. The web is created after multiple components have been produced and is considered scrap material. Press working operations are also known as Sheet Metal OperationsThe operations performed on the sheets to get the required shape is called Sheet metal operations. Subject - Manufacturing Processes MetallurgyChapter - Difference between Blanking Piercing Punching Lancing Notching Process Sheet metal WorkingIn toda.

Source: youtube.com

Source: youtube.com

Modifying slide motion for specific applications. This is a Basic Model Animation of Blanking. If the small removed piece is the useful part and the rest is scrap the operation is called blanking. In the last article we had discussed Types of dies and Types of fits which are performed on Sheet metal to get the required shape. The web is created after multiple components have been produced and is considered scrap material.

Source: m.dragonrest.net

Source: m.dragonrest.net

I started designing from th. Operations such as deep drawing forming coining embossing flow control forming cold forging blanking and conventional progressive or transfer die operations. The design of the center tunnel console is also particularly ergonomic. Full Tutorial of How to Create a Sheet Metal Blanking Process Animation in SolidworksNote. Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable.

Source: m.youtube.com

Source: m.youtube.com

In this video blanking and punching operation is explained with the help of animation. A typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. The only addition operation needed is the removal of a slight burr. Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable. The web is created after multiple components have been produced and is considered scrap material.

Source: learnmech.com

Source: learnmech.com

This is a Basic Model Animation of Blanking. Explaining the Basic Difference Between Blanking Piercing and Punching Process with the Help of this AnimationSheet Metal FormingShearing ProcessBlanking-. Im Zillu a Motion Graphics Visual Effects Video editor Living in a world where design is not an option I just have to do it. A typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. If the small removed piece is the useful part and the rest is scrap the operation is called blanking.

Source: in.pinterest.com

Source: in.pinterest.com

The only addition operation needed is the removal of a slight burr. Blanking produces the outside features of the component while piercing produces internal holes or shapes. A typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. The design of the center tunnel console is also particularly ergonomic. I started designing from th.

Source: machinemfg.com

Source: machinemfg.com

The design of the center tunnel console is also particularly ergonomic. Punching or blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. Operations such as deep drawing forming coining embossing flow control forming cold forging blanking and conventional progressive or transfer die operations. Press working operations are also known as Sheet Metal OperationsThe operations performed on the sheets to get the required shape is called Sheet metal operations. In the last article we had discussed Types of dies and Types of fits which are performed on Sheet metal to get the required shape.

Source: in.pinterest.com

Source: in.pinterest.com

Full Tutorial of How to Create a Sheet Metal Blanking Process Animation in SolidworksNote. The only addition operation needed is the removal of a slight burr. Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations. In this video blanking and punching operation is explained with the help of animation. Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock.

Source: pinterest.com

Source: pinterest.com

Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable. Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations Ifinfotech posted a video to playlist Manufacturing Processes. Subject - Manufacturing Processes MetallurgyChapter - Difference between Blanking Piercing Punching Lancing Notching Process Sheet metal WorkingIn toda. In this video blanking and punching operation is explained with the help of animation. Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations.

Source: in.pinterest.com

Source: in.pinterest.com

Press working operations are also known as Sheet Metal OperationsThe operations performed on the sheets to get the required shape is called Sheet metal operations. In the last article we had discussed Types of dies and Types of fits which are performed on Sheet metal to get the required shape. The web is created after multiple components have been produced and is considered scrap material. Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable. Blanking produces the outside features of the component while piercing produces internal holes or shapes.

Source: youtube.com

Source: youtube.com

The process requires a triple-action fine-blanking press. Blanking Piercing Punching Lancing Notching Process Working Animation Press Working Operations. A typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. Punching or blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. There is an innovative shifter integrated in its black-panel surface that offers the.

Source: pinterest.com

Source: pinterest.com

The design of the center tunnel console is also particularly ergonomic. I started designing from th. Closing force counterpressure and blanking pressure forces are individually and infinitely adjustable. It is a process by which a hole is cut or torn in metal. The design of the center tunnel console is also particularly ergonomic.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title blanking operation animation by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.

Category

Related By Category

- 49+ Corn husk animals information

- 29++ Chinese year 1968 animal info

- 32++ Do animated gifs work in outlook info

- 22++ Animals in space nasa ideas

- 30+ Dragon nest animation information

- 20++ How to animate over live action ideas

- 20++ Chanel logo animation ideas

- 44++ Animals that went extinct in 2013 ideas

- 37++ Disney pixar animals information

- 31+ Bodyweight animal exercises info